Lithium Battery Recycling Plant

Lithium Battery Recycling Plant

At present, the research on the recycling of waste lithium batteries is mainly focused on the recovery of high-value anode precious metals cobalt and lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is an important production raw material widely used.

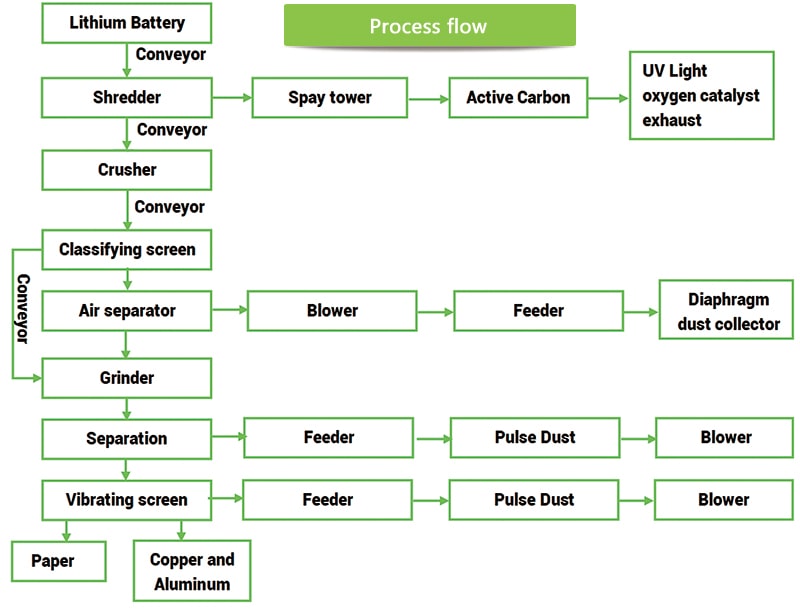

Based on the structural characteristics of lithium batteries, our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries.

Raw Materials:

Lithium battery recycling plant is used for dismantling and recycling the soft package battery, cellphone battery, shell battery, cylindrical battery etc. Different types of lithium batteries have different recycling procedures.

Final Product:

The final product is black mass, copper and aluminum.

Exceptionally, the final product also has separator plastic (non-carbonization solution) and iron shell (only iron shell lithium battery).

Technical Process

The process mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

Technical Standards

| Feature Item | Indicator Requirements |

| Recovery Rate of Metallic Aluminum | >98% |

| Powder Recovery Rate | >98% |

| Content of Powder In Metal Aluminum | <2% |

| Content of Metallic Aluminum in Powder | <2% |

| Other | Contain dust collector with not pollute |

| Black Mass Purity | >99% |

| Copper Purity | >95% |

| Aluminum Purity | >95% |

Technical Parameters

| Model | Capacity |

| ZYLDC-500 | 500 Kg/H |

| ZYLDC-1000 | 1000 Kg/H |

| ZYLDC-1500 | 1500 Kg/H |

| ZYLDC-2000 | 2000 Kg/H |

| ZYLDC-2500 | 2500 Kg/H |

| WORKING PERFORMANCE | |

| Raw Material | Lithium Battery |

| Final Product | Mainly Copper, Aluminum, Black Mass, etc |